JEAN MÜLLER develops and manufactures around 40,000 components for distributing, controlling, securing and measuring electrical energy in low-voltage networks in Eltville am Rhein. For the particularly heavy punching tools of a new product series, the family business was initially only looking for a new transport cart. In the end, the solution was a complete die changing system consisting of a rack system and a lifting cart with integrated docking system and radio remote control.

Jean Müller (JM) uses hundreds of tools for punching, injection moulding and injection compression moulding to produce more than 40,000 different articles. The vertical range of manufacture is high and ranges from product development to toolmaking and component assembly. Most of the company’s international customers are in Europe and Asia. Regular product innovations from our development and efficient production ensure continuous growth, which requires frequent changes.

An adaptation was due in the “Pre-production Metal” department. For many years, the employees there brought stamping tools to their presses using a Serapid transport cart. The device was manoeuvrable and easy to operate, but its maximum load was only 2.5 tonnes. That is too little for the recently used dies to produce stamped parts for the new Tokeo product line switch strips.

Michael Gensecke, JM team leader for metal pre-products, and design engineer Holger Christ started looking for a new cart with a higher load capacity at an early stage. Ralf Depcik, head of production, set the direction. “We wanted the best solution, not the fastest solution.”

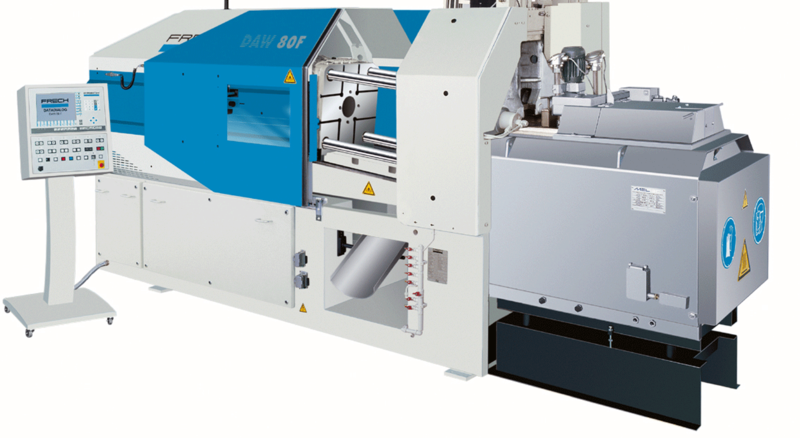

The aim was to find a transport cart for the heavy dies that would enable the presses to be set up quickly and safely. It should also be easy to operate and offer good ergonomics. Because of several narrow places with less than 3 metres of manoeuvring space around a 2.5-tonne Andritz Kaiser and a 1.6-tonne Hydraulick Roos press, the cart also had to be very manoeuvrable.

Furthermore, it was crucial that the dies could be used without conversions and inserted effortlessly and safely on the machine table and rack at lifting heights of between 300 and 1,800 mm. Finally, a remote control was desirable.

With the specifications, Gensecke and his team set out to find the right supplier. Three suppliers were shortlisted.

However, none of the transport carts on the market fulfilled all the requirements. The model from a large supply for press set-up technology came very close to the ideas but, in the end, was not convincing in the practical test: Its turning radius was too large. Since the dies are held magnetically during travel, part of them would also have had to be converted. Also, the retention force was insufficient to transport heavy dies safely.

JM found a suitable solution at the set-up time optimiser ROEMHELD. Teams of both companies together developed an individual complete system for optimal set-up. A procedure that proved successful, according to Gensecke: “We planned and coordinated a lot and also had some special requests. In the end, everything worked out well.”

Andreas Reich also found the development partnership fruitful: “We also learned a lot through the intensive exchange. We are pleased, as well, that we were able to implement additional requirements for the rigidity of the racks, the approach of the cart and the securing systems quickly and to JEAN MÜLLER’s satisfaction.

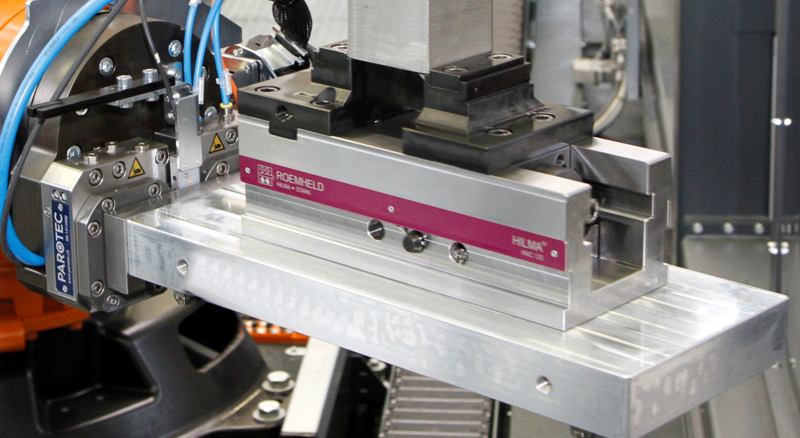

The heart of the joint solution is the exceptionally manoeuvrable, electrically driven ROEMHELD die changing cart type RWA 4000 up to 4t load. It has a die changing table with integrated hydraulic ball bars and a pull-push system that facilitates the automatic insertion of the dies on the press bed.

During transport, the hydraulic balls in the table of the changing cart are lowered and the die is secured against slipping. A safety circuit ensures that the RWA 4000 only moves when the ball bars are lowered. Removable safety bars at the front and on the sides of the support surface additionally secure the die.

The lifting platform is also equipped with an overhang for transferring the die. The cart can be controlled via a central control panel on the multi-functional drawbar, on which a multi-function display is mounted. Furthermore, the employees can control the most important cart functions by radio with additional remote control.

A pull-push system integrated into the cart allows the dies to be safely pulled from the storage spaces onto it and then pushed onto the press bed - without any physical effort by the setters. As all JM dies have eyelets for the grippers of the pull-push chain, they can be used unchanged in the new set-up solution.

The complete system includes two rack systems with eight die places, especially developed by ROEMHELD, to store frequently used dies close to the machine. The system is equipped with a special safety docking system and roller conveyors. This uniform equipment makes the dies move effortlessly and positioned precisely on all surfaces. After undocking at the rack system or press bed, the balls are lowered and their safety lock is raised. The dies are reliably stored and can no longer move.

TOOL CHANGING CART RWA 4000

The safe transfer of the dies between rack and cart as well as cart and press is guaranteed by docking bars with centring aids. These have been designed so that they can be attached to all elements. This allows the dies to be changed between the different storage locations and presses at any time.

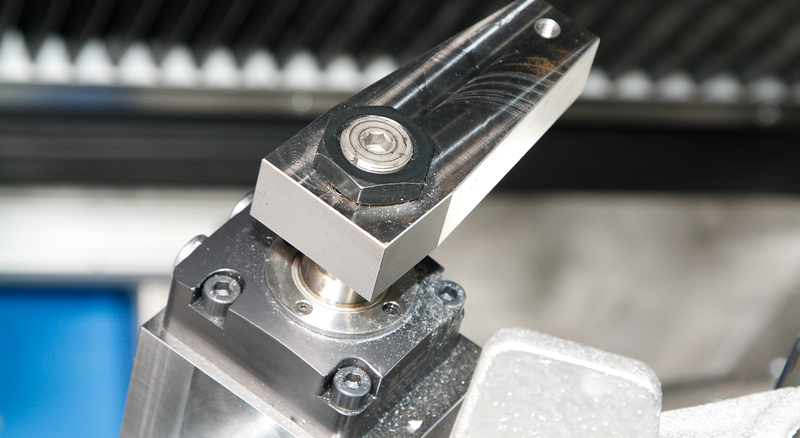

After the dies have been correctly positioned on the press bed, they are clamped there quickly and reliably with the help of hydraulic sliding clamps.

Andreas Reich, product manager of die clamping technology: “The integrated pull-push system is the ideal addition to our extensive range, with which we develop individual complete systems for die change on punching and forming lines. As with JEAN MÜLLER, we thus enable efficient die changes and ensure consistently high press productivity.”

The pull-push system offered by ROEMHELD for several years can move dies up to 50 t into and out of the press via a chain drive. It is screwed directly to the press bed, where the chain transports the die at a speed of 33 mm/s. Faster versions with a maximum of 200 mm/s are also available. A guide of the dies is not required depending on the extension length. The system can also be supplied with a separate control on request.

As in Eltville, rack systems, clamping elements and die centring systems can also be included in the overall solutions. With different solutions, they can be precisely adapted to the respective requirements of the production site. Clamping elements from the standard range as well as ball or roller bars in the press bed and in the changing cart ensure a consistently safe, fast and rational die change. With the transport carts, ROEMHELD also offers a selection of models for different requirements.

In spring 2022, all components were delivered, installed in Eltville and the operators were instructed in one-hour training sessions. Since then, the solution has been in continuous use in three-shift operation. The success: The distances of the dies from the rack to the machine have become shorter, and the duration of the up to three changes per shift has been shortened by about 15 minutes each. Michael Gensecke is satisfied all around: “Products, delivery and service are top. Everything works very well and flawlessly.”

Mevlüt Kücükler, who has been working as a setter on the presses at JM for 32 years, sees the advantages in everyday life: “In the past, we had to lift the dies onto the press with the crane and the forklift and position them there manually. That was time-consuming and exhausting. Now the change is easier: nothing is moved manually anymore; it’s much more convenient, faster, more practical and also very safe.”

And production manager Depcik explicitly emphasises the cooperation with ROEMHELD: “We have done good development work together, learned a lot from each other and achieved an excellent result. I am not sure whether this would have worked out so well with other suppliers.”

ROEMHELD sees itself as the worldwide market leader in die clamping technology for sheet metal forming. As a set-up optimiser, the group of companies solves almost every clamping task in sheet metal forming, plastics and rubber processing with its extensive portfolio of die clamping technology. The magnetic, hydraulic and electro-mechanical clamping systems are versatile and contribute to making processes in single and series production of nearly all industries more efficient and economical. Products for die change, such as die changing carts, roller bars and driven carrying consoles complete the product range.

APPLICATION VIDEO

Die change on a press with the electrically driven die change carriage type RWA 4000 up to 4t load.

Founded in 1897, JEAN MÜLLER is today a leading company in the field of low-voltage technology. With over 500 employees at its headquarters in Eltville am Rhein and more than 600 employees worldwide, JEAN MÜLLER is one of the largest employers in the Rheingau region. Core activities are developing, producing and distributing low-voltage high-power fuses, fused switchgear as well as cable distribution cabinets and low-voltage distribution boards. JEAN MÜLLER offers high-performance measurement data acquisition systems and thus contributes to developing new network structures and analysing consumption in modern industrial complexes.

In 2022, the company celebrated its 125th anniversary. During this period, JEAN MÜLLER developed from a small craft business into an internationally active company with customers in more than 60 countries.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.