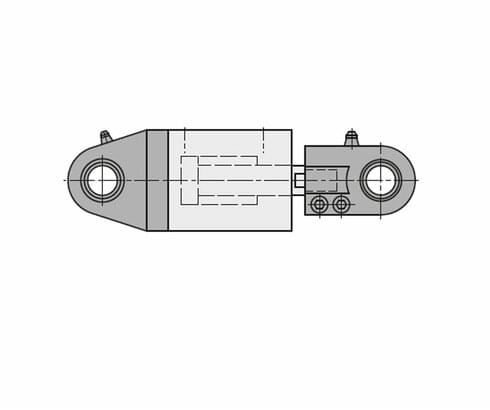

Block cylinders (10)

For all hydraulically operated linear movements.

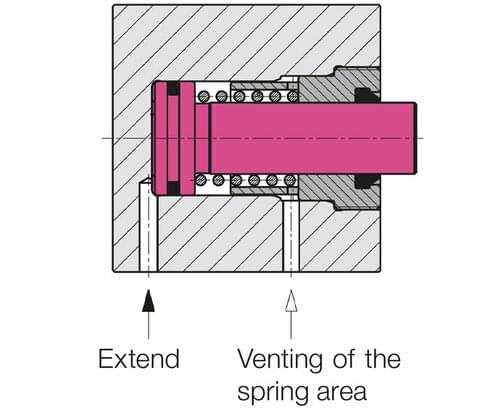

The hydraulic force acts only in one axial direction.

The return stroke is effected by spring force or by external forces.

Venting of the spring area

If there is any danger that fluids penetrate through the sintered metal air filter into the

spring area, a vent hose has to be connected and be placed in a protected position

(see data sheet G 0.110).

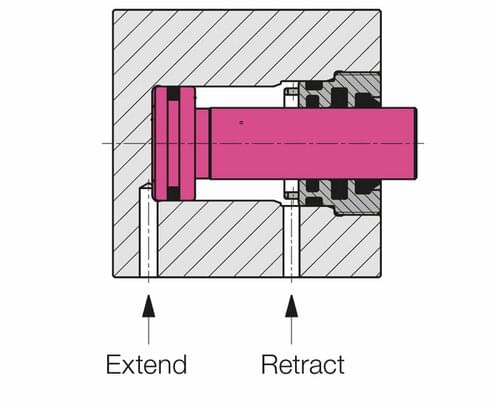

The hydraulic forces act in both axial directions, whereby the force to push is always higher than the force to pull. The double-acting block cylinder has a high functional safety with exactly calculable rimes required for the stroke.

The table values of 0.25 m/s and 0.50 m/s are based on data provided by the seal manufacturers. Apart from two exceptions, the block cylinders have no stroke end cushioning. To avoid damage, the piston should not move at this speed against the internal piston stops without braking.

Admissible piston side load

If the piston rod is loaded with a side load, higher wear must be expected. For strokes

up to 50 mm, the side load should not be higher than 3 % of the max. piston push force.

The block cylinder S and the hydraulic block cylinder are equipped with high-quality guide rings. The admissible side load can be taken from the diagrams on the data sheets.

Seals and max. operating temperature

The data in the chart ar approximate values:

- NBR = Nitril-Butadien-Rubber

Trade name e.g. Perbunan

Temperature range – 30 … + 100 °C - FKM = fluoro rubber

Trade name e.g. VITON®

Temperature range – 20 … + 200 °C

More detailed information, taking into account the common hydraulic fluids, can be found on data sheet A 0.100.

5 sealing packages are available for the block cylinder S. It can thus be optimally adapted

to pressure, temperature and hydraulic fluid.

Leakage

Block cylinders do not leak oil when static. When extending the piston rod, the double

sealing lets pass only a micro-oil film to ensure the required lubrication of the seals and

thus a high service life.

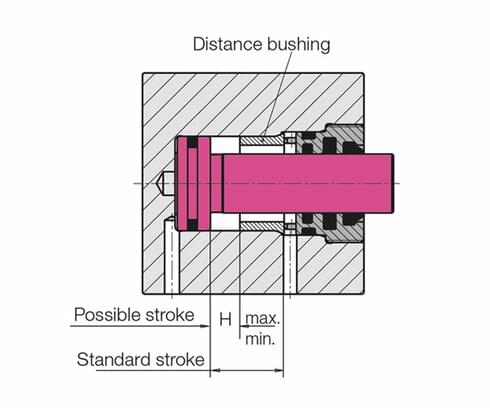

Stroke limitation by distance bushing

Extending of the piston can be limited by the installation of a distance bushing. The minimum stroke shortening is between 3 and 8 mm, depending on the size, and the smallest possible stroke between 1 and 10 mm.

Fixation

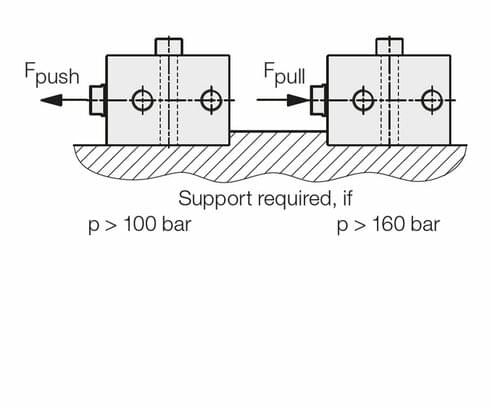

All block cylinders can be fixed with screws of tensile strength 8.8. When fastened across the cylinder axis, block cylinders must be supported depending on the operating pressure.

Options Housings and pistons

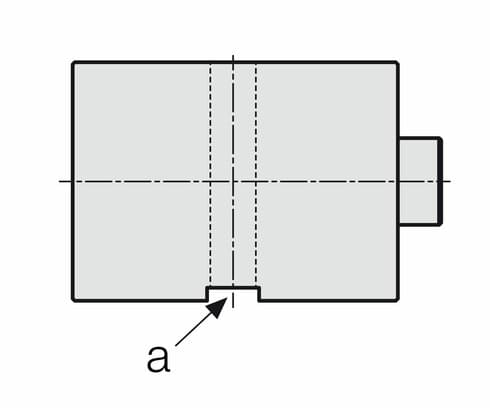

Housing with keyway

If the necessary support on the bottom or rod side is not possible, the cylinder housings can be provided with a keyway.

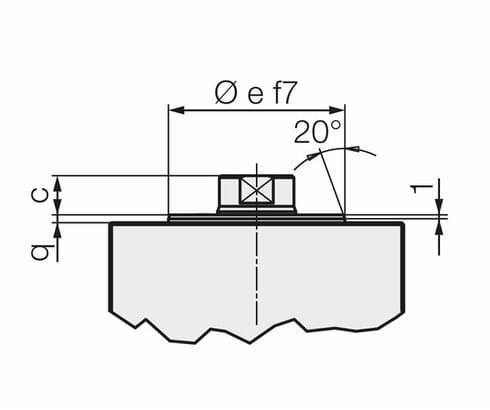

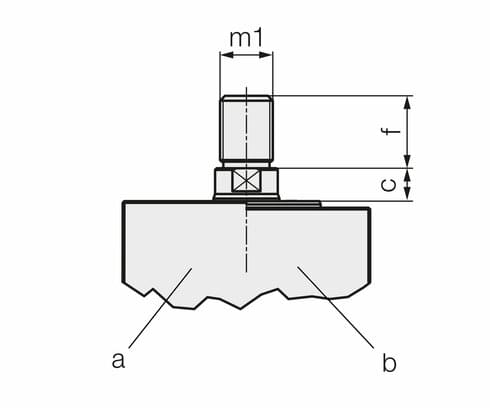

Housing with centring collar

Available for block cylinder S and hydraulic block cylinder.

Piston materials

Case-hardening steel, hardened

High alloy steel, nitrated or chromium-plated

Piston with external thread

Available as variant or special version.

Piston with stroke end cushioning

The damping effect can be adjusted for block cylinder with stroke end cushioning and hydraulic block cylinders.

Stroke end control

These block cylinders are equipped with pressure-resistant proximity switches. They are adjustable in the range from 1 – 4 mm before the end position.

Position monitoring complete

Is mounted to the cylinder bottom of block cylinders with extended piston rod.

The inductive proximity switches are movable and can monitor the complete piston stroke.

Observe minimum distance between adjacent switching points as per data sheet.

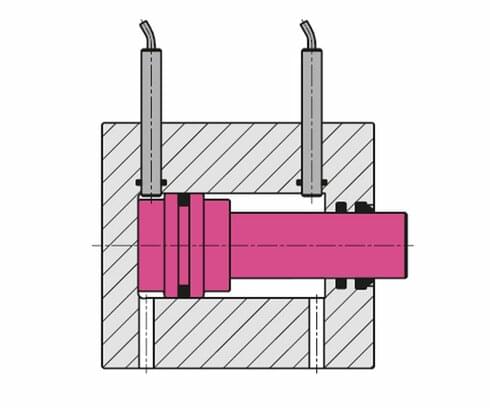

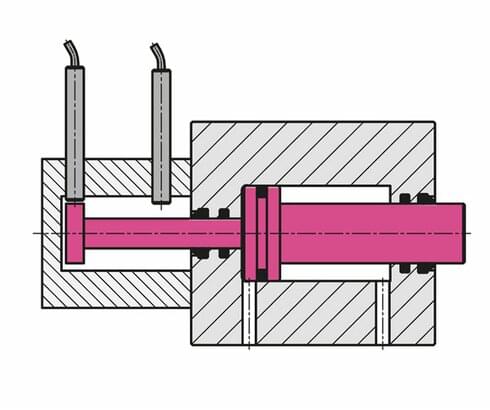

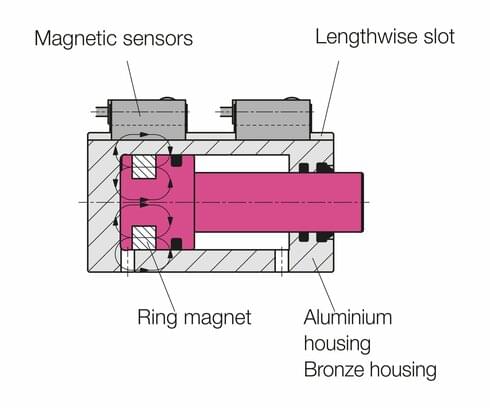

Position monitoring with magnetic sensors

Magnetic sensors are mounted to block cylinders with aluminium or bronze housings in

a trapezoidal slot and can be moved over the entire piston stroke.

Minimum distance of the switching points approx. 6 mm.

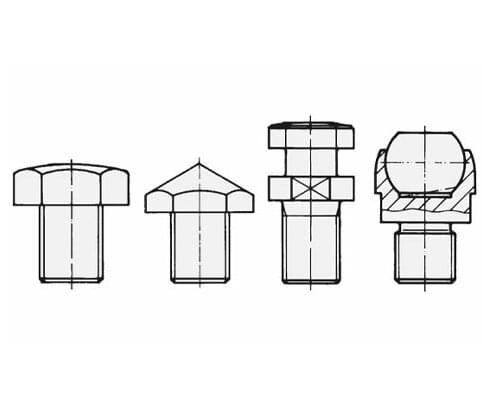

Fittings

Screwed plug with elastic sealing as per DIN 3852 T11 form E and EN ISO 1179-2

Mounting position

any, if not otherwise stated.

Contact bolts and coupling pins

Different contact bolts and coupling pins as per data sheet G 3.800.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.