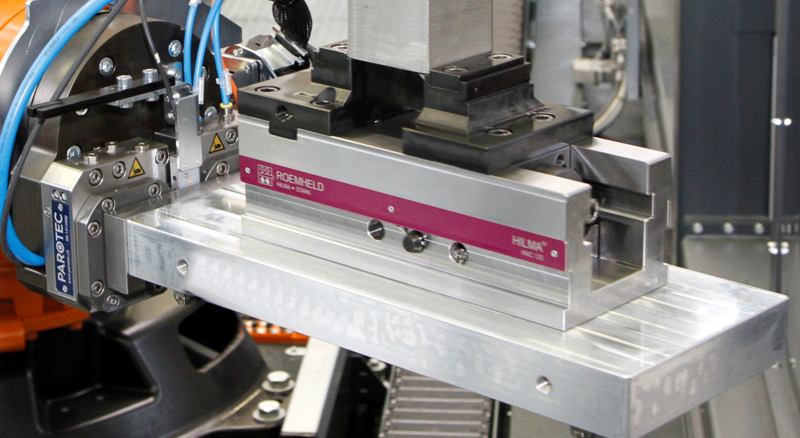

In recent years, the range of applications for magnetic clamping plates as fast and reliable clamping devices for moulds has expanded from plastic and rubber processing to sheet metal forming and even to the die casting industry. Hilma-Römheld GmbH from Hilchenbach in the Siegerland region of Germany is one of the world's leading suppliers of hydraulic and magnetic clamping devices and has been introducing magnetic clamping technology to the die casting industry since 2003.

One of the advantages of these clamping devices is that all mould sizes and shapes, even non-standard ones, can be quickly positioned and clamped; a standardisation of the moulds is not required. They can also be used in a wide variety of applications and are suitable for ambient temperatures of up to 240 °C. Furthermore, existing systems - depending on the application - can generally be easily retrofitted.

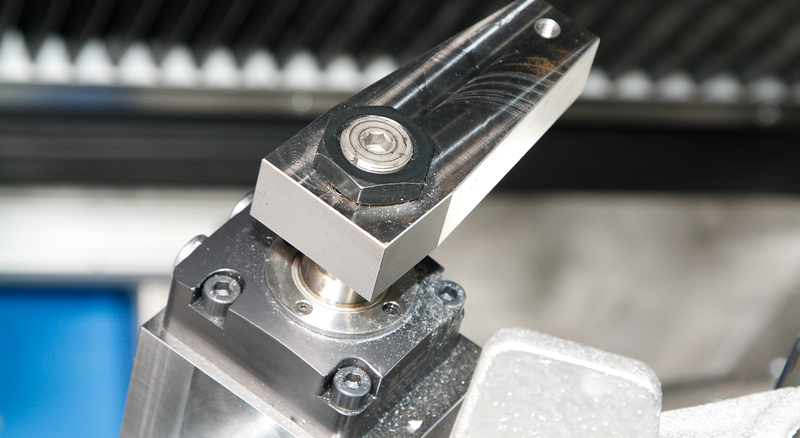

Operation is simple and clamping even in inaccessible places is possible without any problems, which contributes to a high level of work safety on the machine. Low mould wear and high process safety are factors that can be attributed to the low-distortion and extremely precise clamping. Thus, magnetic clamping technology is also well suited for the production of components with narrow dimensional tolerances.

The main reason for their use, however, is usually the time saved when changing moulds. With integrated quick-clamping systems consisting of magnetic clamping plates, die changing carts, coupling technology and preheating station, hot moulds up to 240 °C can be changed by just one person ready for production in a short time. As a result, machine set-up times can be reduced by up to two hours per mould change.

While no special modifications had to be made to the magnetic clamping technology for use in plastics and rubber processing, die casting made special demands. In cooperation with Oskar Frech GmbH & Co. KG from the Swabian town of Schorndorf, Hilma was able to demonstrate its technological competence. The manufacturer of die casting machines is one of the world's leading suppliers of hot chamber and cold chamber technology.

In 2006, Oskar Frech's design engineers were looking for an alternative to hydraulic quick-clamping systems or mechanical clamps for use in hot chamber die casting, enabling simple, fast and flexible mould changes. Two customers from the zinc casting industry approached the Swabians and wished for clamping equipment capable of enabling frequent mould changes in small series without reworking the tools. After the team around design manager Jürgen Kurz had tested various magnetic clamping technologies, they decided on the clamping devices from Hilma-Römheld GmbH.

The company from Siegerland is one of the leading experts for mould clamping and effective mould change in mechanical engineering, forming technology and the plastics and rubber industry. They develop, produce and distribute individual clamping systems and standard fixtures for production worldwide, whereby magnetic clamping technology plays an important role. As a member of the ROEMHELD Group, Hilma is represented by sales and service companies in 39 countries on all continents.

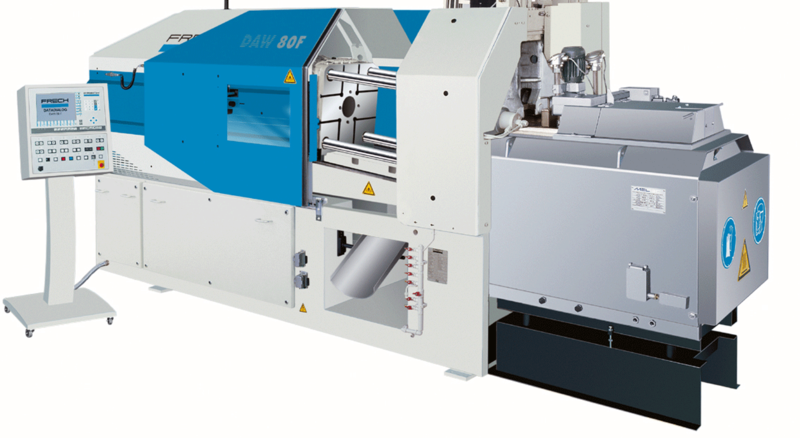

Besides the mentioned requirements, the Swabian design engineers regarded Hilma's magnetic clamping technology as advantageous because the system is intrinsically safe, can be easily operated by the customer and the control could be easily integrated into their own die casting machines. It was also crucial that the time saving in set-up times compared to the use of clamping claws was up to 40 minutes per operation.

Restrictions are specified by the materials used: The processing of aluminium and magnesium produces very high temperatures of around 650 °C, which would destroy the magnetic plates in the long run. Therefore, the technology is not used here. In zinc die casting with processing temperatures of around 420 °C, the moulds are only heated to 180 °C so that magnetic clamping technology can be used. The temperature must be distributed continuously and evenly over the entire mould, since fluctuations of more than ten degrees impair the quality of the cast product. The constant temperature distribution due to the elimination of the clamping slots is another advantage of magnetic plates.

Various modifications had to be made to the control system to adapt the system to the special production conditions in die casting: Due to closure forces of between fifty and eighty tons with mould weights of up to 400 kilograms, very high ejection forces for the cast product could arise in hot chamber die casting when opening the moulds. If magnetic clamping technology had been used, operating errors and malfunctions could have occurred without changes to the control software. There would have been the risk that the mould could move in the case of uncontrolled ejection of the cast products, resulting in an error message and machine standstill. However, by limiting the ejection forces on the system side, this danger could be averted without great effort.

After the integration of Hilma technology into the zinc hot chamber die casting machines of the series “DAW-F”, Oskar Frech delivered three machines to customers in other European countries in 2007. Since then, the machines have been in constant production at the users without any troubles, design manager Kurz reports on satisfied customers. The evaluation phase will continue until the end of 2009, and then the chief designer and his team will assess the experiences. He sees future fields of application for magnetic clamping technology in die casting, especially for customers from zinc casting with frequent mould changes in small batches, for which shorter set-up times and the associated productivity increases bring noticeable cost savings.

We are here for you.

Do you have questions about your customer account, enquiries or orders? Please feel free to contact us.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.