Automated Workholding System HILMA.ASH

jaw widths 125 mm

Hydraulic double-acting

jaw width 125 mm

The long-stroke offers sufficient flexibility for the fully automated production of workpieces for initial and subsequent clamping.

Special features of the HILMA.ASH 125 machine vise family:

- economic: fully automated production

- flexible: for different sizes of component families

- compact: optimum accessibility

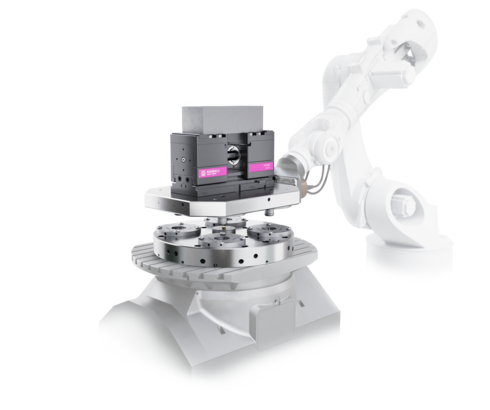

HILMA.ASH automated workholding system

The hydraulically double-acting long-stroke HILMA.ASH clamp is characterised by its long-stroke of 80 mm.

This machine-vise is ideal for different sizes of component families that are clamped in one workholding system. Therefore, the number of workpiece-specific clamping devices can be significantly reduced and clamping tool costs can be saved. Another advantage: The machine running time is not limited by the number of clamping tools and pallets.

The long-stroke offers sufficient flexibility for the fully automated production of workpieces for initial and subsequent clamping.

An automated jaw change is also possible. This means that, without manual intervention and without problems, raw parts and semi-finished products can be held and machined alternately with different clamping forces.

In conjunction with a handling system (e.g.: robot), the HILMA.ASH replaces a large number of conventional workholding systems, which often only have a few millimetres of stroke and therefore offer little flexibility. Families of parts can be produced much more economically with the HILMA.ASH than with standard vises or pallet systems thanks to shorter set-up times and lower personnel and system costs.

- hydraulic actuation, double-acting

- 125 mm jaw width

- hydraulic stroke up to 80 mm

- Automation-compatible design with wipers and central lubrication

- Compact design for optimum accessibility even with small workpieces

Jaw change

- automated changing of clamping jaws (quick-change jaws)

- mechanical changing systems

+ flexible changeover operations

+ raw parts and semi-finished products can be clamped and machined with different clamping forces without manual intervention

Long stroke - high clamping force

- hydraulic stroke up to 80 mm

- compact design

+ optimum accessibility combined with a large stroke provide maximum flexibility in automation

+ ideal for different sizes of component families

Optional position measuring system

- optionally left or right

- automated setting of new clamping ranges

- configured clamping & unclamping

- short strokes in clamping/releasing operation

+ increased process reliability & repeatable production

+ lower personnel and system costs

Design stable - maintenance free

- automation specific design

- central lubrication

+ high availability

+ durable design

HILMA.ASH on zero point clamping system

- HILMA.ASH automated workholding system on zero point clamping system

- Fast closing plate with 4 elements STARK.classicNG.2 Twister and media duct for clamping/releasing the vise

- Coupling unit with zero-point clamping system (device pallet - handling system) 2 elements STARK.airtec with integrated query

- Connections for handling system, 1x pneumatic connection, 1x signal line with M12 plug connection

- Process reliability

- Release control

- Clamp control

- Release control

- Clamp control

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.