For the production of valve housings for passenger car transmissions, a major German automobile manufacturer ordered a production line consisting of four machining centres including the corresponding fixtures from GROB Werke in Mindelheim.

The workpieces would have been deformed if they had been clamped using conventional clamping with standard components; sufficiently precise machining within the narrow tolerances would not have been possible. The solution was provided by position-flexible clamping elements, which were exactly adapted to the application.

“The classical workpiece clamping on three fixed supports with an additional support perpendicular to the surface to be machined does not work because the intrinsic stability of the components is too low”, Key Account Manager Dietmar Wahl from the clamping technology specialist ROEMHELD in Laubach, Hesse, summarises the initial situation in retrospect.

The workpieces would already deform too much due to the vertically acting contact force of the support. The alternative solution was an additional lateral clamping of unstable workpiece areas with position-flexible clamping elements. With the position-flexible clamping elements from the catalogue, it was already possible to achieve a minimal displacement of the workpiece during clamping, but not yet the required process capability. “For this reason, we had to develop an application-specific special solution.”

In automated production, the aluminium castings consisting of a valve housing and the corresponding cover are machined via four stations on various machining centres. The housing is 400 mm long and 21 mm thick, with numerous channels for regulating the transmission oil. The dimensions of the cover are 350 mm and 24 mm. In the first three stations, the component sides are roughened and the holes are drilled one after the other.

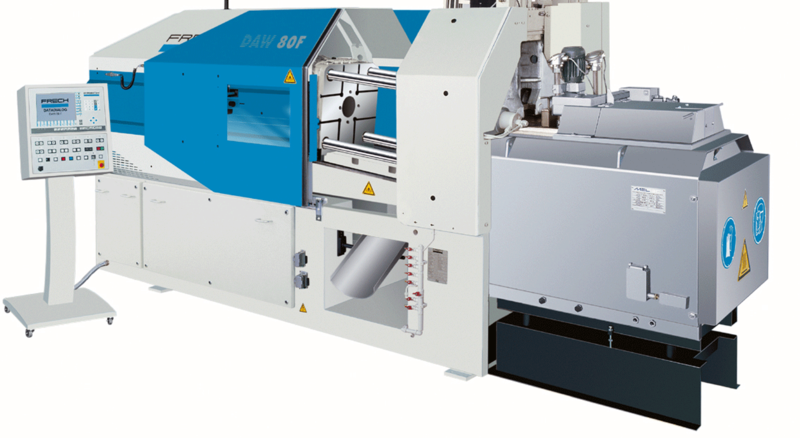

The final step in the fourth station is the fine machining of the surfaces on a single-spindle special model of the GROB G320 machining centre with four axes and an especially massive compound slide. The machine with a 20 kW spindle drive and working paths in X/Y/Z of 615 / 655 / 630 mm is designed for the simultaneous machining of two workpieces. A total of around 480,000 of these demanding components are to be produced per year.

The bridge is automatically loaded and unloaded in a horizontal position. For machining, it swivels by 90 degrees into the vertical position. Then the surfaces of the valve housing and cover are removed by a total of 0.2 mm in two operations, first by 0.17 mm and then by 0.03 mm during finishing. A special milling tool with a diameter of 440 mm is used, which completes both machining steps in about one minute. An integrated measuring probe checks the accuracy of the machining process at predetermined reference points on the workpiece surface.

“The flatness tolerance over the entire workpiece length is 0.05 mm, the specification for straightness over a length of 100 mm is 0.03 mm”, describes Sebastian Dichmann, fixture designer at GROB in Mindelheim, the specifications regarding the accuracy of the component. These tight tolerances represent a special challenge. An already existing clamping concept from a previous project served as the basis for the fixture. This had to be adapted to the new components by the 28-year-old mechanical engineer and converted from wet machining to dry machining.

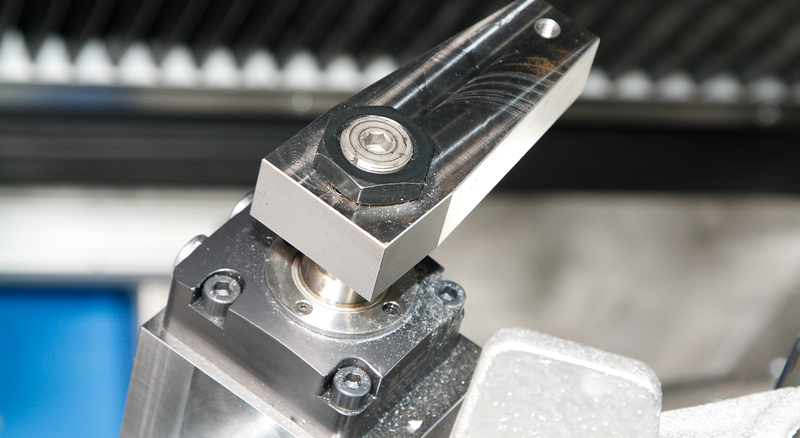

After about two weeks of design, Dichmann had completed the revision in early 2014. The workpieces were to be clamped at three clamping points specified by the customer. Swing clamps with fork head at the end of the piston rod were used as clamping elements. As soon as the clamping arm is swivelled in, the workpiece is clamped with a defined clamping force of 2.25 kN per clamping point.

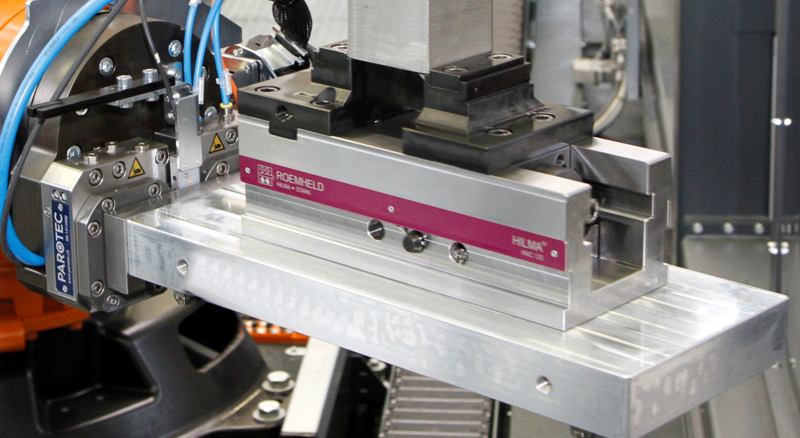

For reliable, distortion-free clamping, six additional position-flexible clamping elements are applied: two on the valve housing and four on the cover. These elements are small vices with two movable slides which are operated by a common hydraulic connection. Thus, the workpiece will be clamped nippers-like and floating, independently of its position within the clamping area.

“Position-flexible clamping elements are used primarily for supporting and clamping unstable workpiece areas without side load and distortion. They adapt themselves to the position of the clamping point without deforming it. At the same time they have a vibration-damping effect and absorb machining forces from all directions”, Benjamin Nagel, responsible for product management at ROEMHELD, describes the purpose of the clamping device.

“Position-flexible clamping elements were also used in the original template for the new fixture, which must have already been used for precise machining”, says Dichmann. During start-up of the adapted fixture, however, it turned out that the required tight tolerances were not always reliably maintained, the designer reports: “At the clamping points of the position-flexible clamps, the components shifted vertically by up to 0.03 mm upwards. The process capability required by the customer could not be met.

In close cooperation with Sebastian Dichmann, the ROEMHELD clamping technology experts looked for a solution - and quickly found it, says the designer: “A position-flexible clamping element with specially adapted slides should provide a remedy. The clamping device was manufactured in Laubach in great haste, as the acceptance of the machining centre was imminent.

The challenge for the clamping device experts was to make the optimised slides sufficiently smooth and sensitive despite the reduced clearance. Otherwise, the two clamping jaws might have moved unevenly, which could have led to a stroke difference with a one-sided displacement force and a distortion during clamping. “We were able to eliminate this danger”, says Nagel. To consider all eventualities, ROEMHELD engineers also checked the customer's clamping jaws and calculated them, but did not find any need for action. Today, it is clear that the clamping elements meet all requirements. “Also because of possibly penetrating swarf due to dry machining, there are no problems”, says product manager Nagel.

The engineers' efforts led to the desired success: Thanks to the new position-flexible clamping element for GROB, the deformation of the clamped workpieces was reduced by two thirds to only 0.01 mm, well below the required tolerance limit. After successful acceptance by the customer, nothing more stood in the way of installing the production line at the end of 2014.

Dichmann expressly praises the cooperation with the supplier: “We were under enormous time pressure and therefore I was particularly pleased that the cooperation proceeded extremely quickly. The new position-flexible clamping elements were manufactured and delivered by ROEMHELD very quickly. Also, the communication was excellent and in the end we were pleased, as was our customer.” Since the start of production, the German premium car manufacturer has ordered two additional production lines for valve housings and covers.

3D-Animation "Posiflex-Clamping"

We are here for you.

Do you have questions about your customer account, enquiries or orders? Please feel free to contact us.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.